| Availability: | |

|---|---|

Ensure Personnel Safety in Hazardous Environments

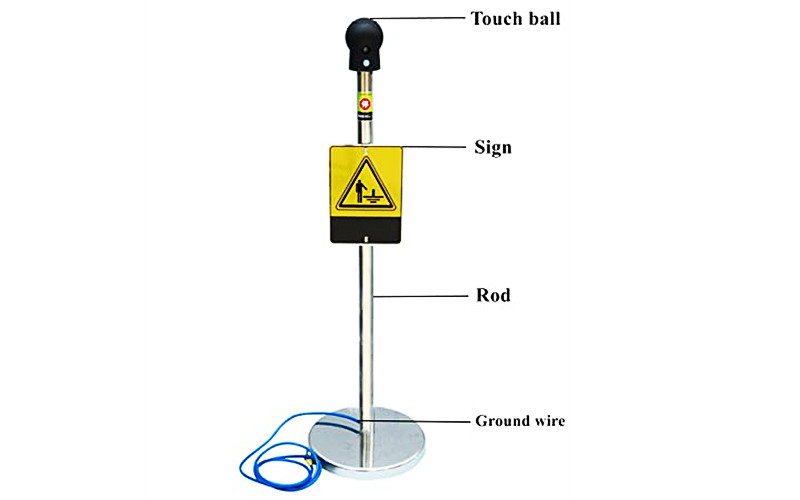

The Toptree Human Body Static Eliminator is a critical safety device designed for flammable and explosive industries. It effectively discharges electrostatic accumulation from the human body to the ground, preventing spark generation that could lead to fire or explosion accidents.

Unlike traditional passive grounding devices, this intelligent static discharge ball features a built-in Sound and Light Alarm System. It provides immediate visual and audible feedback, confirming that the static electricity has been successfully removed, ensuring total peace of mind for operators in petrochemical plants, gas stations, and electronic workshops.

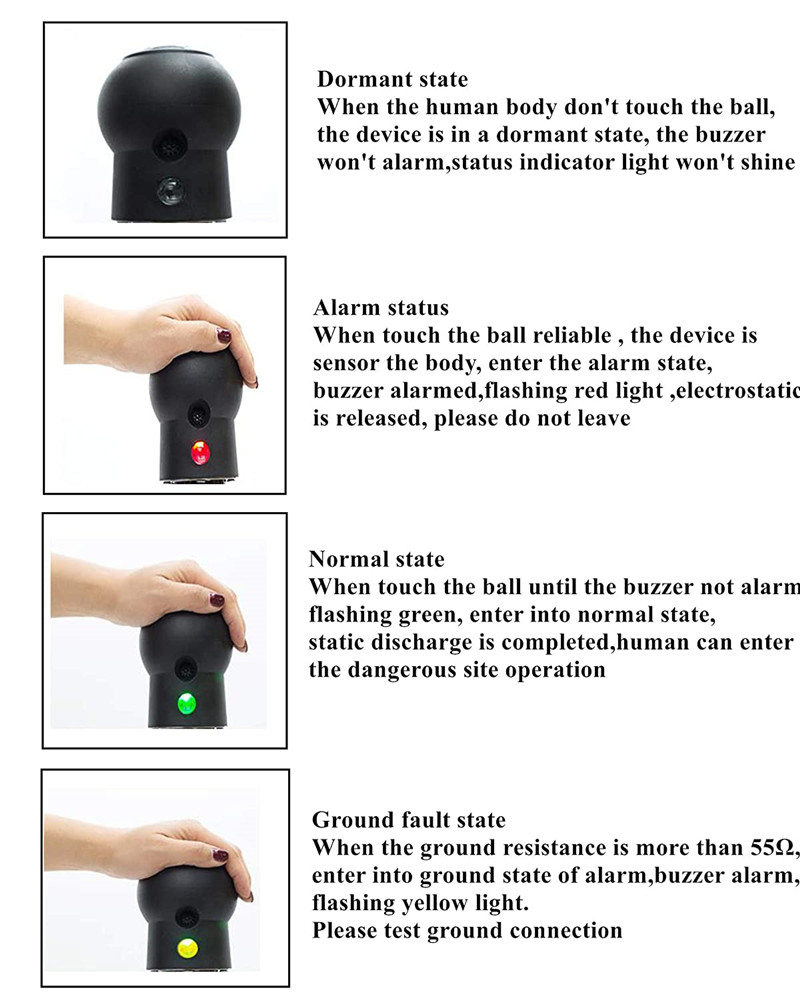

● Audible & Visual Alarm

The built-in alarm system triggers a sound and light signal when static is detected and stops once the discharge is complete, ensuring the user is safe to proceed.

● Touch-Sensitive Discharge

Equipped with a 90mm diameter touch ball that ensures a large contact area for effective and comfortable static dissipation.

● Durable Stainless-Steel Construction

The contact ball and tube are made of corrosion-resistant 304 stainless steel, suitable for long-term use in harsh industrial environments.

● Wide Temperature Range

Designed to perform reliably from –50°C to +100°C, covering extreme outdoor and indoor working environments.

● Simple, Fast Installation

Compact structure with an installation bracket for easy and flexible mounting at access points, gates, and entry booths.

● Suitable for Hazardous & Anti-Static Zones

Designed specifically for locations with strict ESD control requirements.

| Specification | Details |

| Model Name | Human Body Static Eliminator with Alarm |

| Total Height | 1.1 m (Standard) |

| Touch Ball Diameter | 90 mm |

| Material | 304 Stainless Steel |

| Alarm Type | Sound and Light (Audible & Visual) |

| Grounding Cable | 3 Meters |

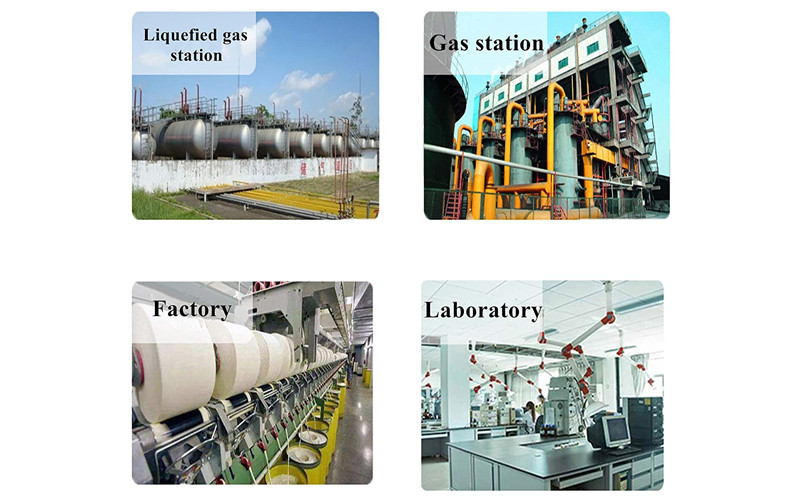

| Application Areas | Gas Stations, Oil Depots, Chemical Plants, Warehouses |

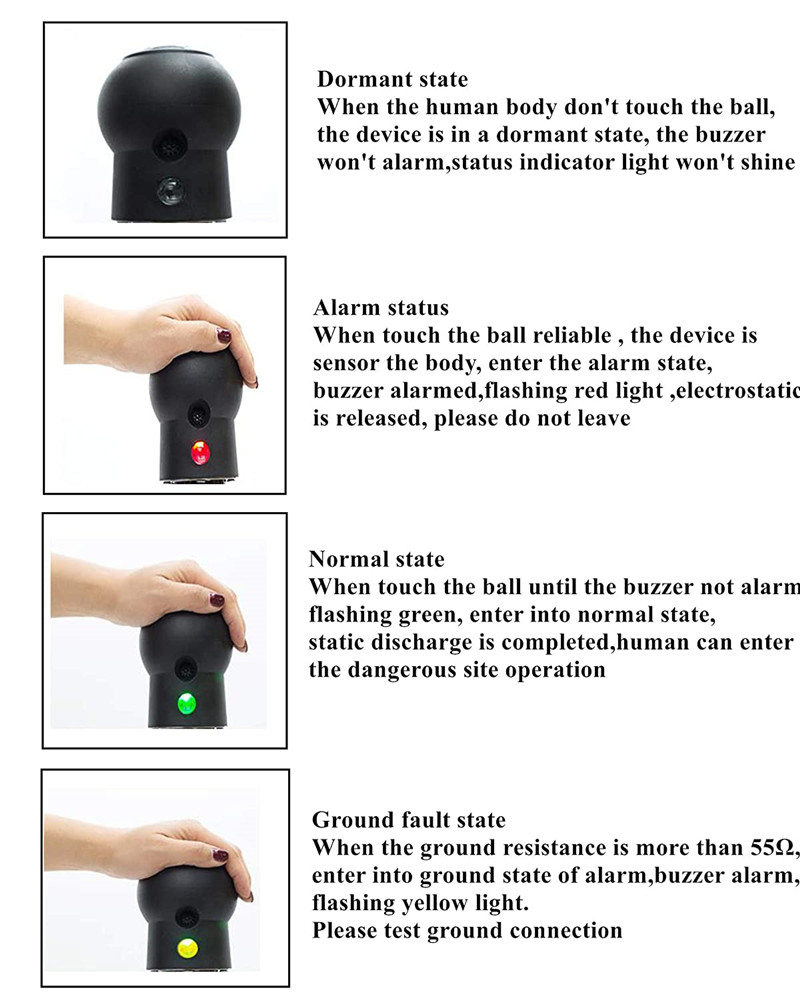

1. Stop:

Locate the device at the entrance of the hazardous zone (e.g., oil unloading port or workshop door).

2. Touch:

Place your hand on the 90mm touch ball.

3. Discharge:

The device detects static voltage on the human body.

The Sound and Light Alarm will activate to indicate the discharge process.

Hold for approximately 1 to 3 seconds until the alarm confirms the static is neutralized.

4. Enter:

Once the alarm indicates safety, you may enter the working area.

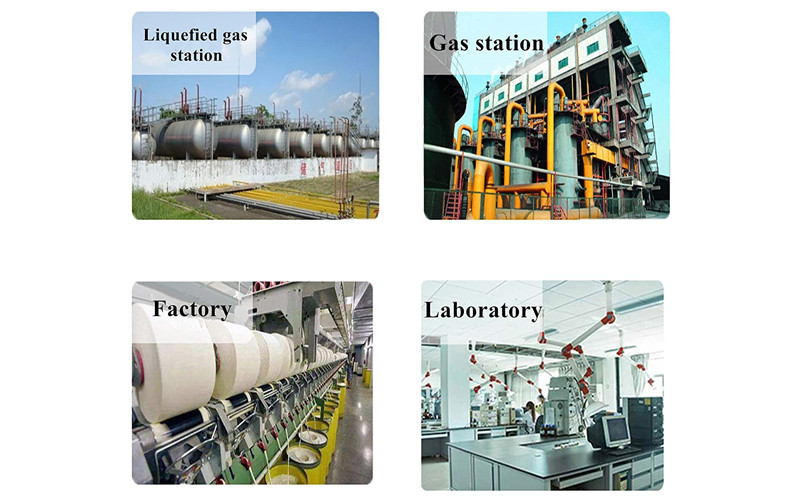

● Chemical plants and petrochemical facilities

● Oil & gas loading and storage areas

● Metallurgy and industrial manufacturing workshops

● Electronics assembly & semiconductor workshops

● Powder processing and spraying facilities

● Hazardous environment access checkpoints

● ESD control zones & sensitive production lines

Uncontrolled static electricity can:

● Ignite flammable vapors

● Damage sensitive electronic components

● Cause shocks to personnel

● Interrupt production processes

● Increase safety risks in hazardous zones

Toptree's static eliminator provides a reliable, maintenance-free solution to prevent static-related incidents.

Ensure Personnel Safety in Hazardous Environments

The Toptree Human Body Static Eliminator is a critical safety device designed for flammable and explosive industries. It effectively discharges electrostatic accumulation from the human body to the ground, preventing spark generation that could lead to fire or explosion accidents.

Unlike traditional passive grounding devices, this intelligent static discharge ball features a built-in Sound and Light Alarm System. It provides immediate visual and audible feedback, confirming that the static electricity has been successfully removed, ensuring total peace of mind for operators in petrochemical plants, gas stations, and electronic workshops.

● Audible & Visual Alarm

The built-in alarm system triggers a sound and light signal when static is detected and stops once the discharge is complete, ensuring the user is safe to proceed.

● Touch-Sensitive Discharge

Equipped with a 90mm diameter touch ball that ensures a large contact area for effective and comfortable static dissipation.

● Durable Stainless-Steel Construction

The contact ball and tube are made of corrosion-resistant 304 stainless steel, suitable for long-term use in harsh industrial environments.

● Wide Temperature Range

Designed to perform reliably from –50°C to +100°C, covering extreme outdoor and indoor working environments.

● Simple, Fast Installation

Compact structure with an installation bracket for easy and flexible mounting at access points, gates, and entry booths.

● Suitable for Hazardous & Anti-Static Zones

Designed specifically for locations with strict ESD control requirements.

| Specification | Details |

| Model Name | Human Body Static Eliminator with Alarm |

| Total Height | 1.1 m (Standard) |

| Touch Ball Diameter | 90 mm |

| Material | 304 Stainless Steel |

| Alarm Type | Sound and Light (Audible & Visual) |

| Grounding Cable | 3 Meters |

| Application Areas | Gas Stations, Oil Depots, Chemical Plants, Warehouses |

1. Stop:

Locate the device at the entrance of the hazardous zone (e.g., oil unloading port or workshop door).

2. Touch:

Place your hand on the 90mm touch ball.

3. Discharge:

The device detects static voltage on the human body.

The Sound and Light Alarm will activate to indicate the discharge process.

Hold for approximately 1 to 3 seconds until the alarm confirms the static is neutralized.

4. Enter:

Once the alarm indicates safety, you may enter the working area.

● Chemical plants and petrochemical facilities

● Oil & gas loading and storage areas

● Metallurgy and industrial manufacturing workshops

● Electronics assembly & semiconductor workshops

● Powder processing and spraying facilities

● Hazardous environment access checkpoints

● ESD control zones & sensitive production lines

Uncontrolled static electricity can:

● Ignite flammable vapors

● Damage sensitive electronic components

● Cause shocks to personnel

● Interrupt production processes

● Increase safety risks in hazardous zones

Toptree's static eliminator provides a reliable, maintenance-free solution to prevent static-related incidents.